Our Core manufacturing capabilities are one of the key services we offer here at NAR Group. With over 50 years of experience in providing advanced cooling solutions, our workshop can provide some of the finest radiators and cooling components in the UK and worldwide. The cores we manufacture are renowned for their dependable reliability, incredible efficiency and ability to precisely meet the specification required. That’s why we’ve worked in countless fields that demand incredible precision and quality in their automotive cooling solutions, including Defence and motorsport. Interested in learning more about our advanced core manufacturing capabilities? Read on within this article for more information.

What does NAR Group manufacture?

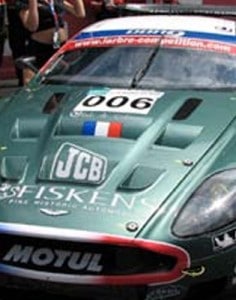

NAR Group can successfully manufacture a cooling component or core to meet the specifications set out for any car and a variety of other vehicles, based upon a drawing or supplied pattern. We provide clear proof of our prowess in our shop on this very site, where you’ll find replacement parts for a variety of leading automobile brands such as Jaguar and Aston Martin, renowned for their quality. All of our cores are designed, developed and hand-built in our own factory.

What are our Core Manufacturing Capabilities?

Our in-house workshop at NAR Group utilises the latest innovations alongside tried and tested methods to ensure your cores are manufactured to the highest quality possible. With our over half a century of experience and prowess in cooling solutions, alongside the latest innovations, our core manufacturing capabilities are truly extensive.

We manufacture over 100 different tube and fin combinations using 12 multi-functional fin machines and 7072 corrosion-resistant tubing material. Our core builders use the latest in semi-automatic building for a synthesis of the benefits of both an automatic and hand-built approach. We use a camlaw vacuum batch furnace for quick and cost-efficient production of prototypes and small-batch projects for economical design. We perform extensive core testing via pressure decay and UV testing rigs. When it’s time for full production to begin, we assemble our cores with CAB controlled atmosphere brazing and utilise a Seco Warwick active semi-continuous belt cab furnace for efficient and premium-quality batch production.

All of this combined allows us to produce some of the finest quality automobile cooling components via a top-quality core manufacturing process. You can rest assured that every NAR Group part produces has undergone extensive testing and a manufacturing process that utilises the finest equipment available for unmatched quality in your advanced cooling solution.

NAR Group hopes this guide has revealed to you the impressive extent of our core manufacturing capabilities. As a leading UK provider of advanced automobile cooling solutions for sectors ranging from defence to motorsport, we pride ourselves in applying our 50+ years of experience to the best of our ability in our innovative manufacturing processes. NAR Group also offers component assembly, fabrication and remanufacturing services and products for a variety of services. Contact our team or browse the rest of our site today to learn more about what NAR Group can provide for you.